- Main Facilities

-

- SQUID Magnetometer(Quantum Design MPMS-XL-a)

- Physical Property Measurement System(Quantum Design PPMS-9T)

- 16/18T high homogenity superconducting magnet(for NMR)

- MPMS-XL-a,b

-

- -7 < H < 7 T (MPMS-XL-a).

- -5 < H < 5 T (MPMS-XL-b).

- 2 < T < 350 K (MPMS-XL-a&b).

Only experienced users can excancahge DC/RSO heads (MPMS-XL-a&b).

In RSO case, users must not use any heavy item such as a pressure cell.mpms hardware namual (pdf)

mpms Multi-Vu manual (pdf)

SQUID calibration using a Pd standard sample (pdf, japanese only)- Oven option : 300 < T < 700 K (MPMS-XL-a only)

The manual for oven option lies in a cabinet beside PPMS (booklet japanese only)

Only experienced/highly instructed users can use this option.

Users never install this option by themselves.

With regard to sample mount, beginner must contact to an administrator, any way.- AC-susceptibility option : 1 < f < 1 kHz (MPMS-XL-b only)

- MPMS-XL-a noise report (Sorry no english version)

1st (pdf, SQUID detection devices check, 2024/01/30-31)

2nd (pdf, Magnet control devices check, 2024/02/13-17)

3rd (pdf, DC, RSO, comparison, 2024/03/18-21)

- PPMS

-

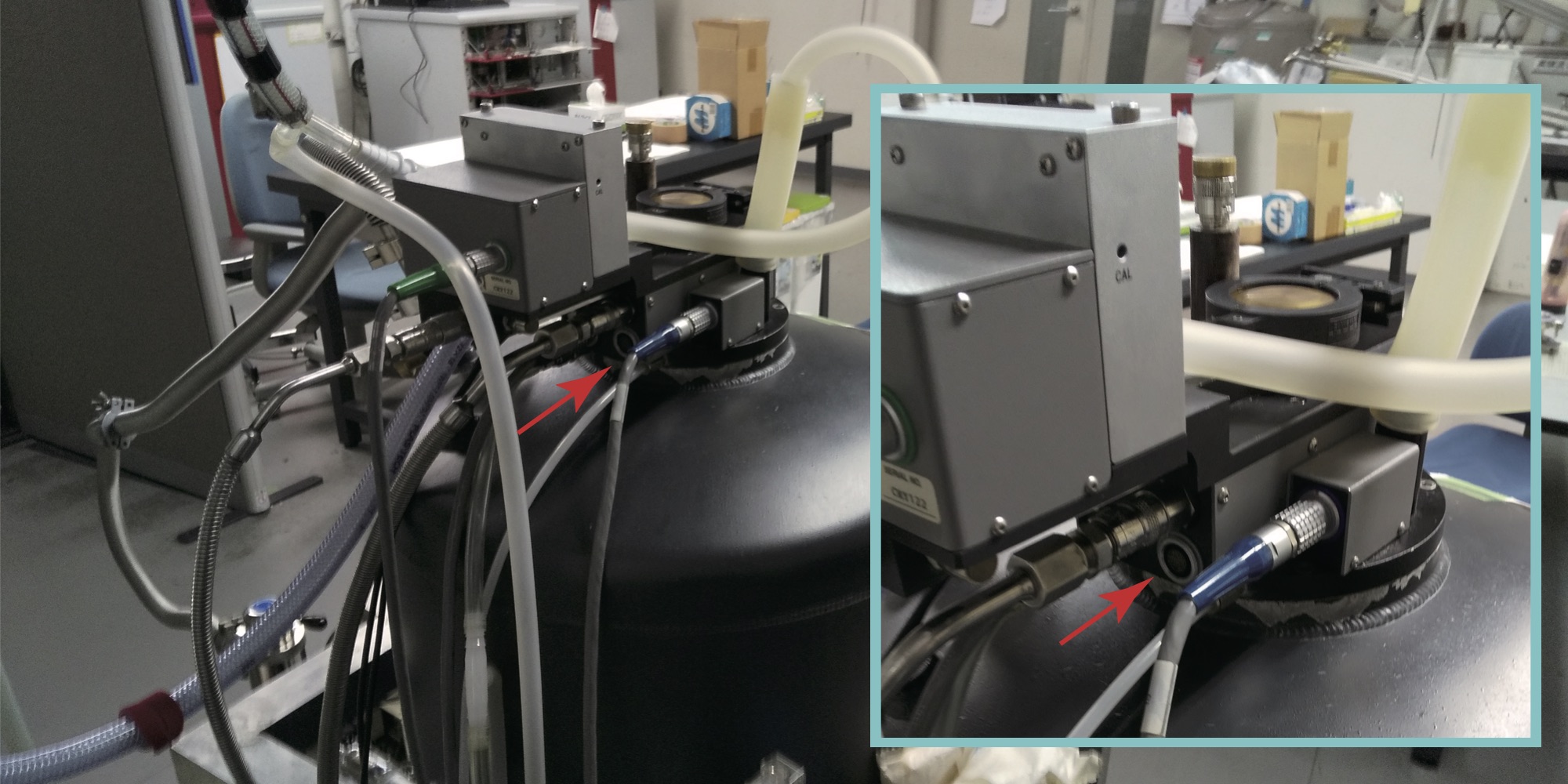

Users must connect the gray-Lemo suitable for desired options by themselves.

- -9 < H < 9 T

- 2 < T < 350 K

- AC/DC electronic transport.

DC/AC sample pucks should basically be prepared by users.

However, if you plan to use the ppms only 2 to 3 times, you can rent one from the electromagnetic room.- Horizontal Rotator

The sample pack for rotator conforms to the DC/AC sample pack.

If acetone etc. are applied to the wiring of the rotator, damage of several million yen will occur. Please be careful.- Multi-function probes

Every your setup must be checked (taking ~1 hour, only in business hours) before starting measurements,.

Air leak to the sample chamber may cause several-million-yen severe damages.ppms hardware manual (pdf)

ppms resistivity option manual (pdf)

ppms horizontal rotator option manual (pdf)

ppms Multi-Vu manual (pdf)

- Application for registration

-

Application for registration on our PPMS/MPMS-XL-a requires your well understanding the rules noted below.

After checking the schedule shown below, you can email to the emag address (not to gmail) using the "application template". To anyone in ISSP who wants to use a MPMS-XL-b, see a system B information page (Japanese only) for your reservation.- "rules for application"

#1. Upto 8 days per one month.

#2. Upto successive 3 days in weekday (Excluding remote persons with accommodation).

#3. Upto successive 8 days including saturday and sunday (ex. Wed-Ths-Fri-Sat-Sun-Mon-Tus-Wed).

#4. Application for next month open at 20th in this month 0:00 (Excluding remote persons with accommodation), first come, first served.

#4-1. PPMS needs your another action to get yourn machnine time (see the calendar below, but sorry for its japanese descriptions).

#5. In case no registration at next 72 hours, everyone can apply for these days, even if your days exceed the maximum 8 days.- "rules for use"

#1. Run the "log-mpms/ppms". Make a log-file (named "yyyymmdd.env" or "-.dat", every 60 sec, taking all the data) at a specific folder.

#2. Every user setup (such as multi-function probe in ppms) must be checked by ME, before starting your measurements.

#3. Report every trouble. (In emergency case, you can call a mobile phone of administrator : the number is shown at A056)

#4. Liquid-He and -N2 baths of ppms/mpms must be filled up by users at the end of your measurements.

#4-1. When you see a small abount of Liquid-He less than 30 L in the vessel, you must return the vessel to ISSP Cryogenic Service Lab as soon as possible.

#4-2. Substitution of Liquid-He vessels (see the calendar) and refilling for the Liquid-N2 vessel mus be done in a timely manner.

#5. Your measured data must be extracted by the emag-method (It will be instructed at your first use).

#6. Finish measurements at 10:00 am (ex. 3rd-5th day resv. : from 3rd 10:00am till 6th 10:00am).

#7. Any item you brought (including sample) must not be left.

#8. Cleanup the desk you used (Be careful of separating garbage).- "application template"

1. apparatus : mpms-a/mpms-b/ppms

2. term : yyyy/mm/dd ~ yyyy/mm/dd

3. your name/affiliation :

3. your (mobile) phone num :

4. measurements : M-T/M-H/R-T/R-H/etc..

5. temperature/field range : 2-350K, 0-7T(mpms-a), 0-5T(mpms-b), 0-9T(ppms)

6. sample (chemical formula) :

7. note for the sample (poison/radio active etc..) :

- Before your measurement

-

- Be sure to enter the necessary items in the log note (booklet).

# Each ppms/mpms-a has an each log note.The original version of these log notes can be downloaded from these links. When no page for you, you must add the both sides hardcopies for 2 pages of the PDF (Be care its direction) to the booklet of the log note.

- When you have refilled liq-He/N2, fill in a dedicated log note (booklet).

- Run "log PPMS/MPMS".

# Enter the file name of log file into the log note.

# Open a dialog box at "Utilities/Log MPMS Data/" or "Utilities/Log PPMS Data".

# Name the log file as yyyymmdd.env(mpms) or -.dat(ppms). Make this file at

[ppms] c:QdPpms:Data:log:.

[mpms] c:QdMpms:Log Data:.

# Set the sampling rate at around 60 sec.

# Check the sampling items [check box], temperature, field, He-level etc.. (as much as you can).

# Push the "START" button.- Do not forget follows.

# [ppms] Connecting a gray lemo for your desired option.

# [ppms] Every time when user-probes are set up, it must be checked by administrator before starting the measurements (available only in business hours).

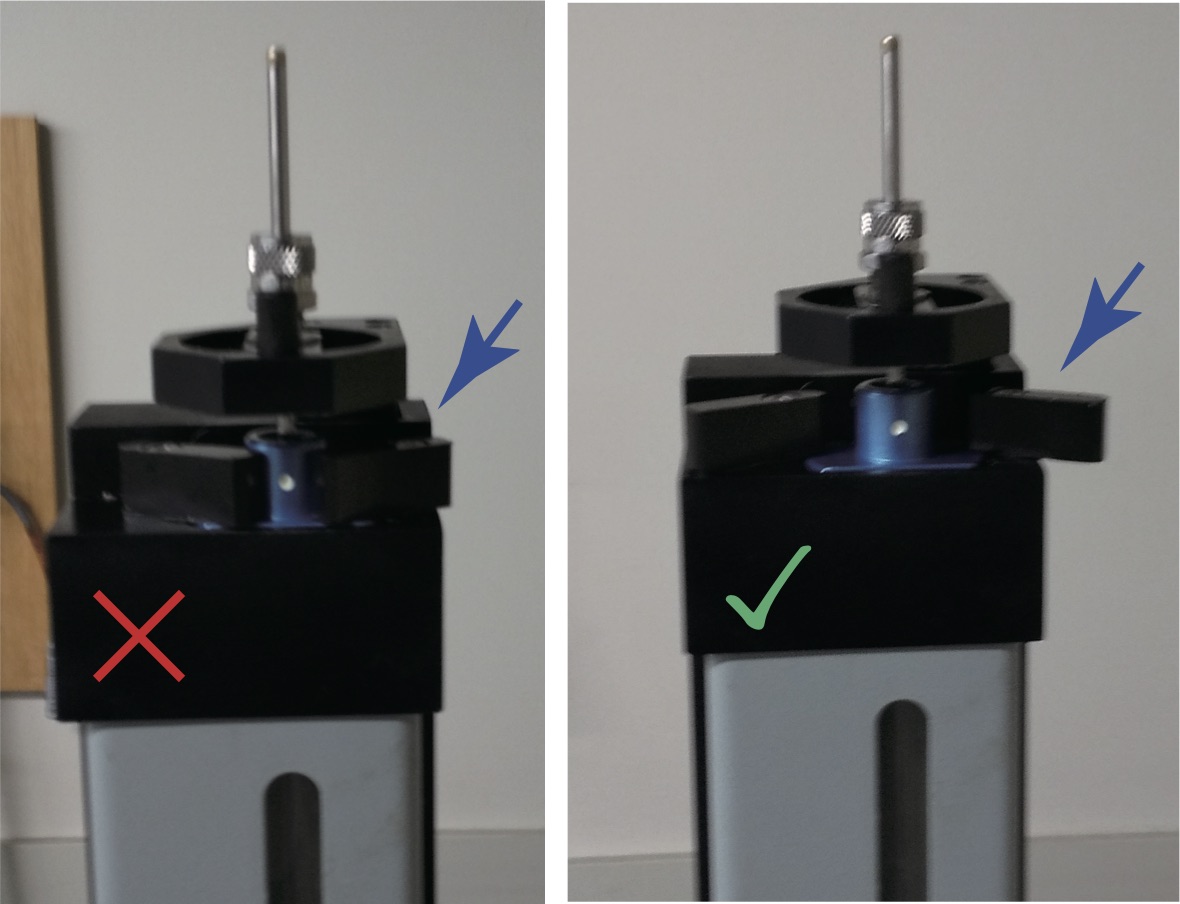

# [mpms] In case of DC-head, check the fixing parts for a slide and seal (a blue part) directs toward right way.

log-note for MPMS-XL-A

PPMS gray-lemo

MPMS probe fixing parts (DC head) - In your measurement

-

- Check the He-levels in ppms/mpms-a. If short, refill it. When you do this, you can operate a valve on the vessel, but must not touch the valves in He-recovery system.

- In both ppms and mpms, when H >1 T, liq-He level must be keep above 50 %.

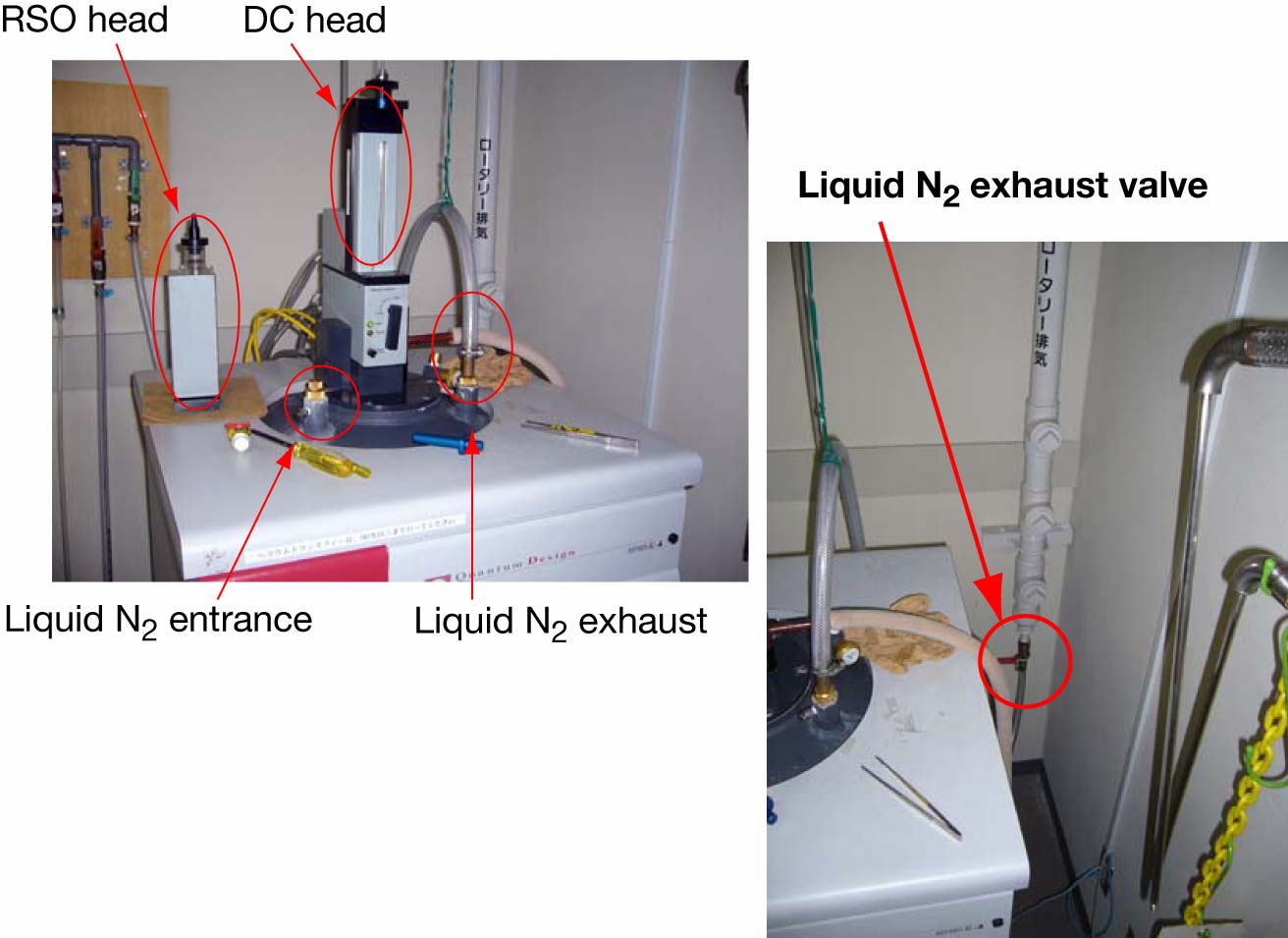

- In case of empty N2 jacket [mpms], it should be refilled ASAP (For refilling, see the N2 exhaust valve sequence).

- Liq-He in a vessel must be remained more than 15 L.

- If it becomes less than 30 L, the vessel must be returned to Cryogenic Service Lab ASAP.

- On basically Wednesday (see the calendar), Liquid-He vessels must be renewed and the Liquid-N2 must be refilled to its vessel in a timely manner.

- Make share that casters of liq-He/N2 vessels are locked.

- After your measurement

-

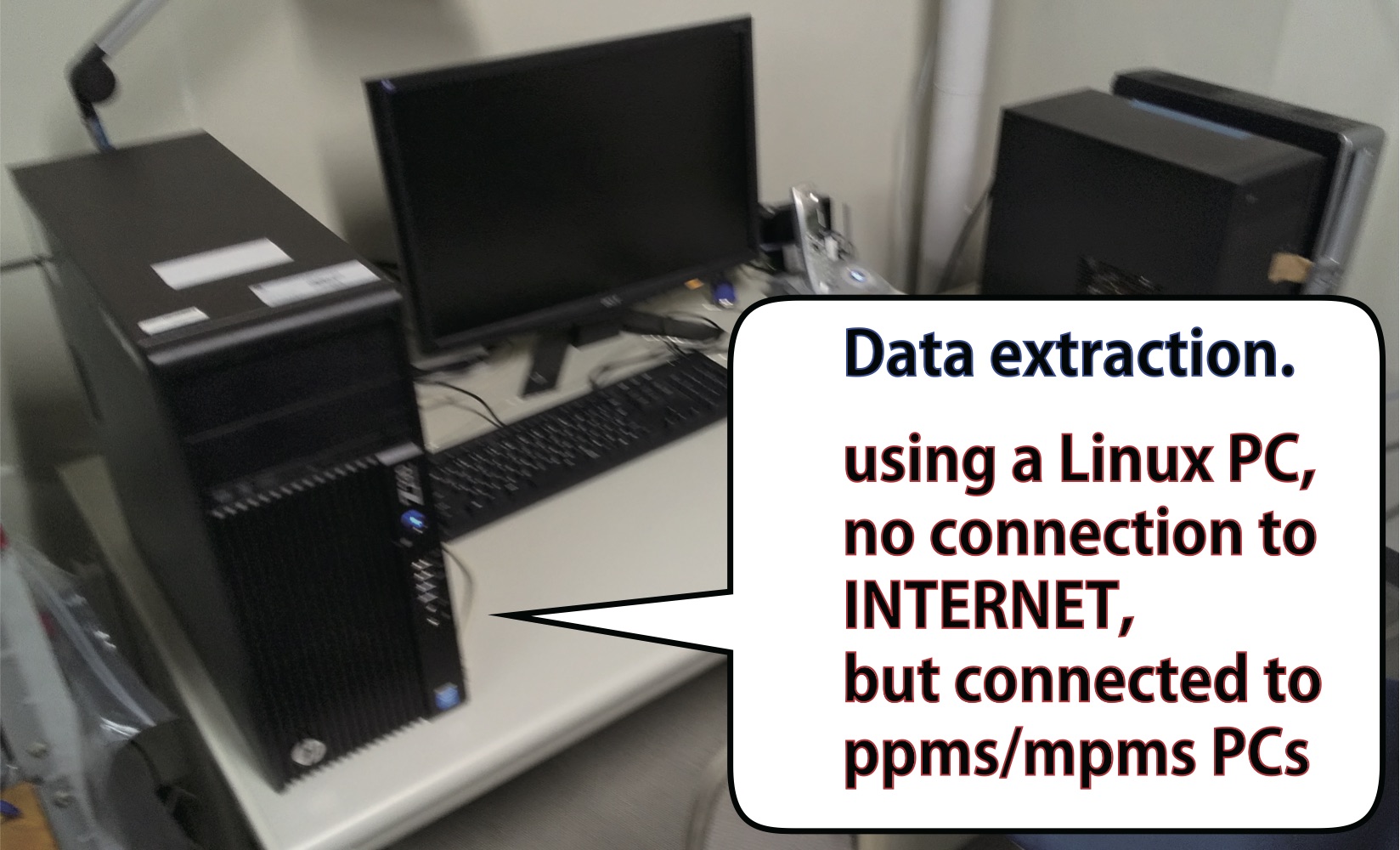

- Data extraction in the emag-method.

No user is allowed to connect a USB mempry to the windows PC for ppms/mpms.

The data extracting method (emag-method) will be instructed at your first use.- Set H =0 Oe.

- The log-ppms/mpms continues to run after your measurements.

- Liquid-He and -N2 baths of ppms/mpms must be filled up by users at the end of your measurements.

Users who can access the liq-N2 sites must refill the N2 vessel.

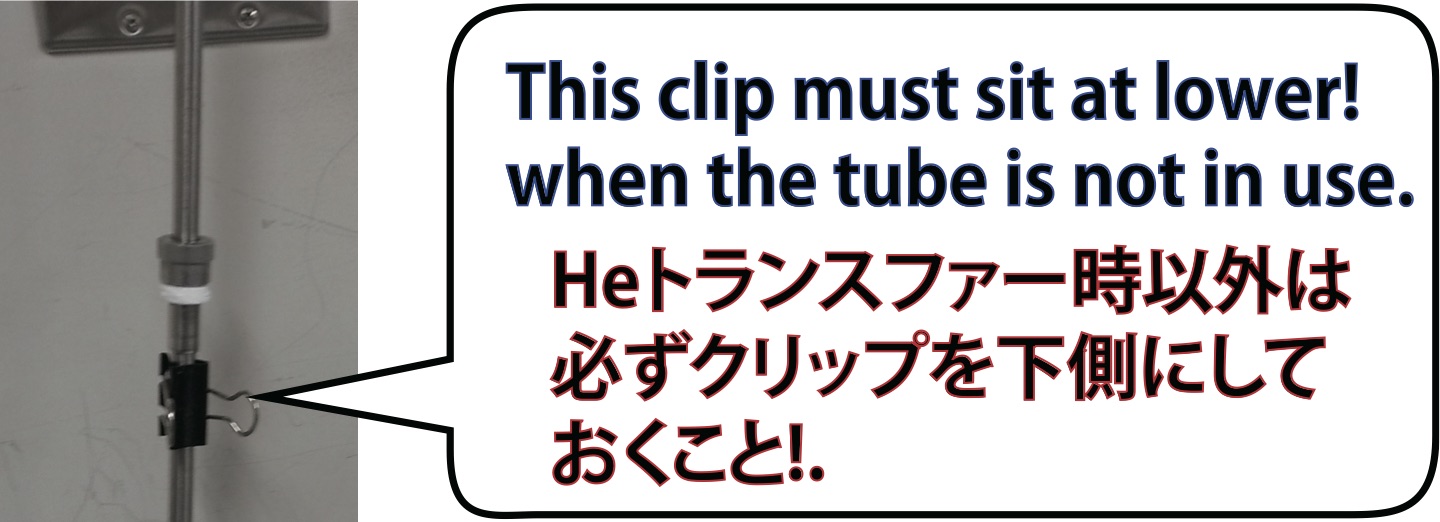

After using a He-transfer tube, the position order of a wilson seal and a clip must be checked!.

If you lose the wilson seal, you will performe metal processing using a precision roll turning lathe in researcher’s machine shop of ISSP.

- Turn the ppms/mpms "standby mode" for reducing liq-He consuming.

standby mode :

[ppms] Instrument/Shutdown ,

[mpms] Instrument/Standby .

After understanding the instructions described at the dialog box, push the "OK". - Turn the ppms/mpms to the "original setting".

[ppms]

Return the gray-lemo to the original position.

A measurement option in Multi-Vu should be de-activated.

Set back "pppms config" file, if you changed it.

After rotator use, send gpib command "usertemp 0" to the model 6000.

[mpms]

Set a DC-head on the mpms.

Check Multi-Vu is not Oven option mode.

- Any item you brought (including sample) must not be left behind you.

- Cleanup the desk and else you used, to make them better than before.

Data extraction linux-PC

Gig for He-transfer tube (Willson seal)

PPMS gray-lemo original position - Contact

-

- Touru Yamauchi

- mail : emag[at]issp.u-tokyo.ac.jp

- office : A163 or A453

- ext : 63499

- mobile phone (only in emergency case, shown at A056).

-

- ****

- Fixed schedule (Users are responsible for returning/bringing He vessel on Wednesday.)

-

- ****

- References

Quantum Design Japan Co. Ltd.

- Before liq-N2 filling up

-

- Open the Liquid N2 exhaust valve shown in the figure. This make the O2 level in this room suitable.

- After liq-N2 filling up

-

- Close the Liquid N2 exhaust valve. If you forget it, you will have a fatal risk such as explosion of N2 jacket in MPMS.